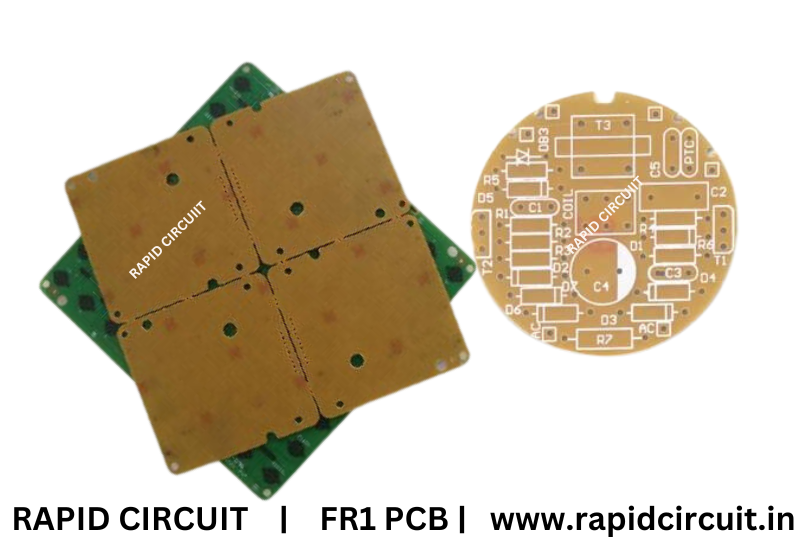

Single Layer PCB

FR1 PCB

FR1 PCB

FR1 PCB refers to a type of printed circuit board (PCB) material. FR1 stands for “Flame Retardant 1” and is a grade of phenolic paper-based laminate. It is a relatively inexpensive and commonly used material for single-layer PCBs. It is an older and less commonly used substrate than more popular options like FR4 (Flame Retardant 4) and FR2.

It’s worth noting that FR1 is unsuitable for high-temperature applications or circuits that generate significant heat, as it has a lower temperature tolerance than other PCB materials, such as FR4 (Flame Retardant 4). FR4 is a more common and versatile PCB material used in a wide range of applications.FR1 PCBs have good electrical insulation properties and are typically used for low-cost applications that don’t require high-performance or complex circuitry. They are commonly found in consumer electronics, lighting products, toys, and other low-power applications.

FR1 is a code used to designate the specific grade of flame-retardant paper-based laminate used in the PCB manufacturing process. It offers moderate electrical insulation properties but has limitations regarding mechanical strength, temperature resistance, and dimensional stability compared to more advanced materials like FR4.

When working with FR1 PCBs, it is important to consider their limitations in terms of temperature, mechanical strength, and electrical properties. If you are designing a PCB and considering FR1 as the material, review its specifications and consult with manufacturers or experts in PCB fabrication for guidance specific to your project.

Here are some key characteristics and features of FR1 PCBs:

Single-layer: FR1 PCBs are typically used for single-layer designs, which means they have circuitry on only one side of the board.

Flame-retardant: As mentioned earlier, FR1 material has flame-retardant properties, making it suitable for certain applications where safety is a concern.

Material: FR1 PCBs are made from paper-based phenolic resin with a flame-retardant additive. The paper-based core makes FR1 PCBs less expensive than other materials like FR4.

Flame resistance: FR1 PCBs have moderate flame-retardant properties, meaning they provide some protection against fire but not as much as higher-grade materials like FR4 or FR5.

Applications: Due to their cost-effectiveness, FR1 PCBs are often used in low-cost consumer electronics and simpler electronic devices where high flame resistance or advanced properties are not required. FR1 is one of the more economical PCB materials, making it a budget-friendly option for projects with basic requirements.

Limitations: FR1 PCBs are suitable for many low to medium-performance applications, but they have some limitations regarding thermal performance and mechanical strength compared to more advanced materials like FR4 or other high-temperature laminates.

It’s important to note that FR1 is just one of several types of PCB materials available, and the choice of material depends on the specific requirements and performance needs of the electronic device being designed. Higher-grade materials like FR4, FR5, and others offer better thermal performance, higher flame resistance, and improved mechanical strength, but they are also more expensive.

Before selecting a PCB material for a project, it’s essential to consider factors such as the application’s operating environment, budget constraints, and the desired performance characteristics of the final product. As always, consulting with PCB manufacturers and design experts can help in making the best material choice for a particular application.