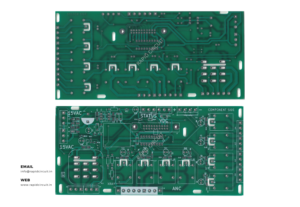

Double sided PCB

DOUBLE SIDED PCBs

A double-sided PCB (Printed Circuit Board) is a type of circuit board that consists of two conductive layers, one on the top and one on the bottom, separated by insulating material called the substrate or dielectric (a non-conductive substrate material), usually made of epoxy or fiberglass. It is one of the simplest and most cost-effective types of PCBs and is commonly used in a wide range of electronic devices and applications.

In a double-sided PCB, electronic components can be mounted on both the top and bottom sides, and the traces on each side can be interconnected using plated through-holes, also known as vias. Vias are small holes drilled through the board and coated with a conductive material, allowing electrical signals to pass from one side to the other, thus creating electrical connections between the top and bottom layers.

The double-sided PCB is the most basic and common type of PCB and is used in a wide range of electronic devices, from simple consumer electronics to more complex applications. It is commonly used for designs with relatively simple circuitry and doesn’t require extensive routing of traces. A double-sided PCB is also known as a PTH PCB, two-layer PCB, double-sided plated thru PCB, and double-layer PCB.

Advantages of a double sided PCB:

- Cost-effective: Double-sided PCBs are generally more affordable to produce, making them suitable for simpler electronic applications with fewer components. Double-sided PCBs are less expensive to manufacture than multilayer boards, making them suitable for cost-sensitive projects.

- Simplicity: With only two layers, the design and layout processes are generally simpler and easier to manage. The design and manufacturing process of 2-layer PCB are less complicated than multi-layer boards, which can lead to reduced development time and cost.

- Easier Troubleshooting: With fewer layers, it is generally easier to troubleshoot and repair any issues that may arise during the testing or manufacturing process.

- Increased Routing Space: Compared to single-sided PCBs, double-sided PCBs offer more routing space, allowing for more complex and densely packed circuit designs.

- Component Density: The ability to mount components on both sides of the board allows for higher component density, making it suitable for more sophisticated electronic designs.

- Flexibility: Double-sided PCBs offer greater design flexibility, as they allow traces to be routed on both sides, enabling designers to create more compact and optimized layouts.

- Better Signal Integrity: With the availability of additional routing space and ground planes on both sides, double-sided PCBs can have improved signal integrity compared to single-sided boards.

- Thermal Dissipation: Double-sided PCBs can handle higher power components and dissipate heat more effectively due to the increased surface area available for heat dissipation.

However, double-sided PCBs also have some considerations:

However, double sided PCBs also have some considerations:

- Cost: Double-sided PCBs are generally more affordable than multi-layer PCBs, but they are typically more expensive to manufacture than single-sided PCBs due to the additional complexity.

- Signal Crosstalk: Without proper design considerations, signals on one side of the board can interfere with signals on the other side, leading to signal crosstalk issues.

- Limited Routing Space: Having only two layers for routing can restrict the complexity of the design, leading to less flexibility in component placement and trace routing.

- Signal Integrity: High-speed or high-frequency circuits might face signal integrity issues due to limited ground and power plane options.

- EMI Considerations: Two-layer PCBs might have less effective EMI shielding and grounding, which can be problematic in sensitive electronic applications.

- Limited routing space: Having only two layers can make routing more challenging, especially for designs with a high component density or complex connections.

- Signal integrity: In complex circuits, signal traces may need to be longer, which can lead to signal integrity issues like noise, interference, and signal degradation.

- Ground and power plane issues: A two-layer PCB may lack dedicated ground and power planes, which can affect electromagnetic interference (EMI) and power distribution.

double sided PCBs find applications in a wide range of electronic devices and industries due to their versatility and ability to handle medium-complexity circuit designs. Some common applications of double sided PCBs include:

- Consumer Electronics: Many consumer electronic devices, such as smartphones, tablets, digital cameras, printers, and home appliances, use double-sided PCBs. These boards provide a cost-effective solution for integrating the necessary electronic components and circuitry within a compact space.

- Industrial Electronics: Double-sided PCBs are prevalent in industrial control systems, automation equipment, power supplies, and instrumentation devices. These boards can handle moderate complexity and offer reliable performance in various industrial applications.

- Automotive Electronics: Automotive control modules, engine management systems, infotainment systems, and other electronic components in vehicles often utilize double-sided PCBs. They provide a balance between cost-effectiveness and functionality in automotive electronics.

- Communication Systems: Many communication devices, such as routers, modems, and networking equipment, incorporate double-sided PCBs. These boards allow for efficient signal routing and can accommodate the required circuitry for data transmission and reception.

- Medical Devices: Medical equipment, including patient monitoring systems, diagnostic devices, and medical imaging equipment, often use double-sided PCBs for their reliable performance and compact design.

- LED Lighting: Double-sided PCBs are commonly used in LED lighting applications. They provide a platform for mounting the LED chips and other electronic components required for driving and controlling the LEDs.

- Audio and Video Equipment: Double-sided PCBs are utilized in audio amplifiers, video players, and other audio-visual equipment due to their ability to handle the necessary signal-processing circuitry.

- Power Supplies: Many power supply units, including linear and switch-mode power supplies, use double-sided PCBs to manage the required power distribution and regulation circuits.

- Security Systems: Various security devices, such as access control systems, surveillance cameras, and alarm systems, incorporate double-sided PCBs to support the necessary electronic components.

- Computer Peripherals: Computer peripherals like motherboards, graphics cards, and expansion cards often use double-sided PCBs. These boards provide a cost-effective solution for the complex circuitry needed in modern computing.

While 2-layer PCBs are widely used, more complex designs may require additional layers to accommodate a higher number of components and complex routing requirements. Multi-layer PCBs (e.g., 4-layer, 6-layer, or even more) offer greater flexibility for intricate circuit designs and better signal integrity in high-frequency applications. However, they also come at higher manufacturing costs. The choice of the number of layers depends on the specific requirements of the circuit and the overall design complexity. Double-sided PCB is Good for low-density designs. It is ideal for circuits with relatively low component density and minimal complexity. Double-layer PCBs strike a balance between cost-effectiveness and functionality in a wide range of electronic applications.

For any Inquiry, Please E-mail to [email protected]