Double-Sided and Multilayer PCBs | Rapid Circuit

Double-Sided and Multilayer PCBs

High-Performance PCB Solutions by Rapid Circuit

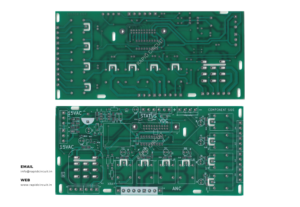

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. Among the various types, double-sided and multilayer PCBs stand out for their ability to support complex and high-performance applications. Understanding their structures, advantages, and applications can help in selecting the right PCB for your project.

What Are Double-Sided PCBs?

Double-sided PCBs feature conductive copper layers on both the top and bottom sides of the board. This design allows for more complex circuits than single-sided PCBs, as components and traces can be placed on both sides, connected through vias.

Advantages of Double-Sided PCBs

- Increased Circuit Density: Utilizing both sides of the board allows for more components and connections in a given area.

- Enhanced Design Flexibility: Designers can create more intricate circuits without increasing board size.

- Cost-Effective for Moderate Complexity: They offer a balance between complexity and cost, making them suitable for a wide range of applications.

- Improved Heat Dissipation: The dual-layer design aids in better thermal management, enhancing the longevity of components.

Common Applications

Double-sided PCBs are widely used in:

- Consumer Electronics: Smartphones, televisions, and audio systems.

- Industrial Controls: Automation systems and control panels.

- Power Supplies: Chargers and adapters.

- LED Lighting: Efficient and compact lighting solutions.

- Automotive Systems: Dashboard controls and infotainment systems.

Exploring Multilayer PCBs

Multilayer PCBs consist of three or more conductive layers, separated by insulating materials. This structure supports high-density and high-speed circuits, essential for advanced electronic devices.

Benefits of Multilayer PCBs

- Compact Size: Multiple layers allow for more functionality in a smaller footprint.

- Enhanced Performance: Improved signal integrity and reduced electromagnetic interference.

- High-Speed Capabilities: Suitable for applications requiring rapid signal transmission.

- Greater Design Flexibility: Supports complex routing and component placement.

- Cost-Effective in Mass Production: Economies of scale reduce the per-unit cost in large volumes.

Typical Applications

Multilayer PCBs are integral to:

- Computing Devices: Laptops, servers, and data centers.

- Telecommunications: Routers, switches, and communication satellites.

- Medical Equipment: Diagnostic and monitoring devices.

- Aerospace and Defence: Navigation systems and control units.

- Automotive Electronics: Advanced driver-assistance systems (ADAS) and infotainment.

Choosing Between Double-Sided and Multilayer PCBs

Selecting the appropriate PCB type depends on several factors:

- Circuit Complexity: Multilayer PCBs are better suited for complex, high-speed circuits.

- Space Constraints: Multilayer designs offer more functionality in limited space.

- Budget Considerations: Double-sided PCBs are more cost-effective for simpler designs.

- Production Volume: Multilayer PCBs become more economical in large-scale production.

What We Offer:

- ✅ Expert Design Assistance – Work with experienced PCB engineers

- ✅ Cutting-Edge Manufacturing – Use of advanced, automated equipment

- ✅ Rapid Prototyping – Fast turnaround for new product development

- ✅ Flexible Volumes – Support for both small and bulk production

- ✅ Reliable Quality Control – Thorough testing for all PCBs

With years of industry experience and a client-first approach, Rapid Circuit ensures that your PCBs meet global standards and performance expectations.

Get Started with Rapid Circuit

Looking for reliable PCB manufacturing solutions?